Cost-intensive failures and unplanned downtimes — not with the energy self-sufficient and maintenance-free monitoring solution from endiio

Thanks to the endiio solution, a costly breakdown in the operation of an international supplier to the automotive industry was prevented.

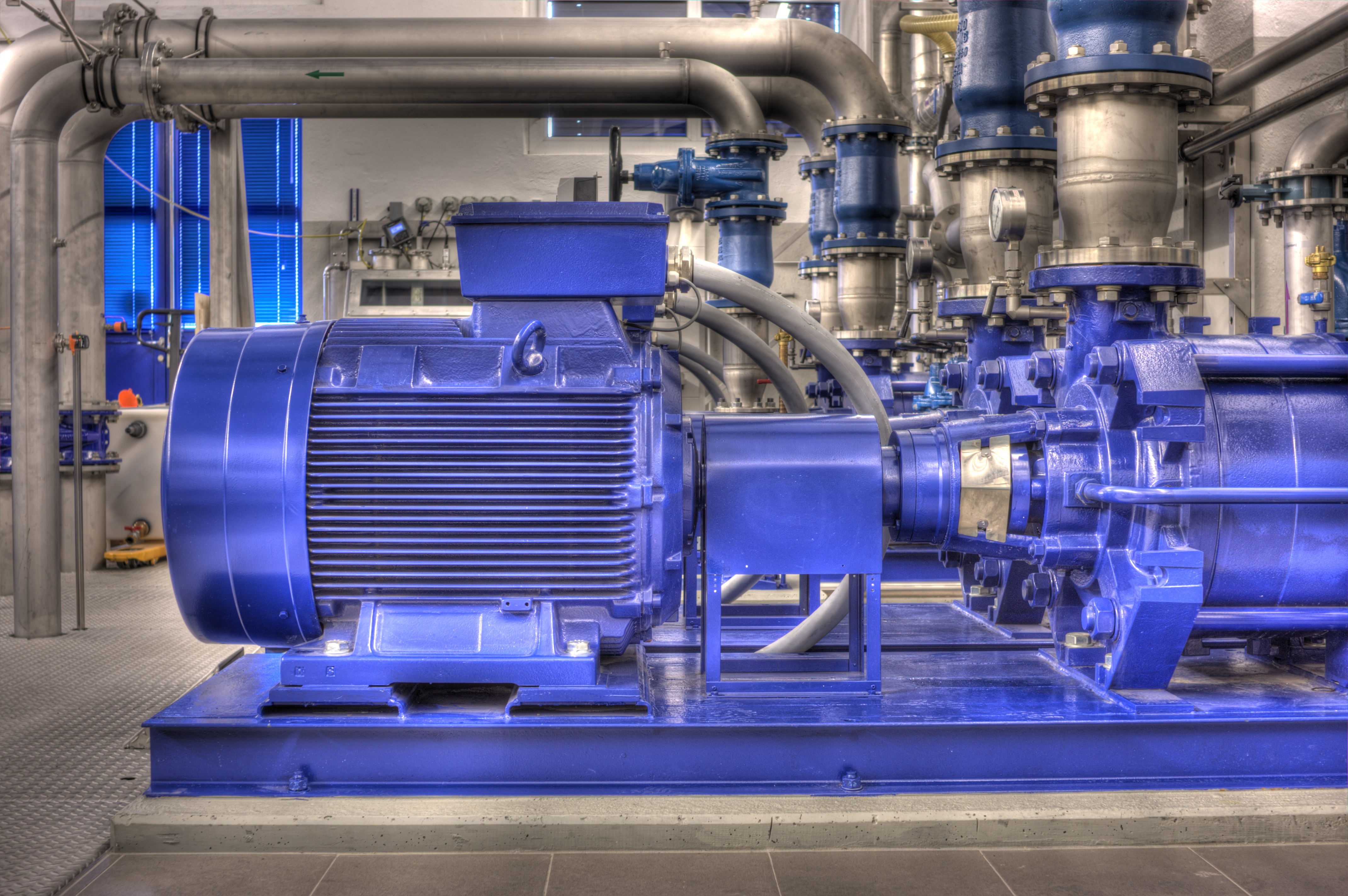

In the past, breakdowns in the company’s electroplating repeatedly led to financial losses due to unplanned downtimes. Due to the low degree of digitization of essential components in this process, the group decided to initiate an IoT pilot project to retrofit these important assets and to establish a predictive maintenance process in order to save costs and increase the efficiency of the systems.

The primary goal of the automotive supplier is to receive early indications of possible damage using automated condition monitoring. The essential core requirements for retrofitting include maintenance-free operation, non-invasive and simple retrofit, as well as compatibility with different drive manufacturers and configurations.

For this purpose, the endiio solution including the Retrofit Box with MEMS sensors, the gateway and the software license was provided. With the innovative retrofit kit, sensor units could easily be retrofitted to the existing drive elements.

The Retrofit Box continuously records measurement data such as magnetic field, vibration and temperature and transmits it wirelessly to the IoT gateway, where it is collected and forwarded to a central asset management.

Due to the long-term monitoring of the data, a change in a drive element could be recognized and the maintenance department was informed.

The trigger was a steadily increasing bearing damage. The early warning made it possible to choose an ideal time for the exchange and repair of the system outside of production times. When looking at the data, an anomaly can be seen about 4 weeks before it occurs.

These anomalies can be learned or trained using EDGE computing software and thus automatically recognized in future operation. This gives the company the opportunity to predict these situations in the future in order to minimize unplanned downtimes and to use planned downtimes more effectively for maintenance.